| 023-8862 6996 139 8336 4953 |

主要(yao)的加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)設備(bei)是(shi)(shi):自動(dong)多(duo)頭連續研磨(mo)(mo)機(ji)(ji)(ji)(ji)(ji)、金剛(gang)石(shi)(shi)(shi)校平(ping)機(ji)(ji)(ji)(ji)(ji)、橋(qiao)式(shi)磨(mo)(mo)機(ji)(ji)(ji)(ji)(ji)、圓盤磨(mo)(mo)機(ji)(ji)(ji)(ji)(ji)、逆(ni)轉式(shi)粗(cu)磨(mo)(mo)機(ji)(ji)(ji)(ji)(ji)、手扶磨(mo)(mo)機(ji)(ji)(ji)(ji)(ji)。3、切(qie)(qie)斷(duan)加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)切(qie)(qie)斷(duan)加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)是(shi)(shi)用(yong)切(qie)(qie)機(ji)(ji)(ji)(ji)(ji)將毛(mao)板或拋光(guang)板按所需(xu)規格尺寸進行定形(xing)切(qie)(qie)割加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)。主要(yao)的加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)設備(bei)是(shi)(shi)縱向多(duo)鋸片(pian)切(qie)(qie)機(ji)(ji)(ji)(ji)(ji)、橫向切(qie)(qie)機(ji)(ji)(ji)(ji)(ji)、橋(qiao)式(shi)切(qie)(qie)機(ji)(ji)(ji)(ji)(ji)、懸臂(bei)式(shi)切(qie)(qie)機(ji)(ji)(ji)(ji)(ji)、手搖切(qie)(qie)機(ji)(ji)(ji)(ji)(ji)等(deng)。4、鑿切(qie)(qie)加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)鑿切(qie)(qie)加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)是(shi)(shi)傳(chuan)統(tong)的加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)方法,通(tong)過楔裂、鑿打(da)、劈(pi)剁、整(zheng)修、打(da)磨(mo)(mo)等(deng)辦法將毛(mao)胚加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)成所需(xu)產品,其表(biao)面(mian)可以(yi)是(shi)(shi)菠蘿(luo)面(mian)、龍眼面(mian)、荔枝面(mian)、自然面(mian)、蘑(mo)菇面(mian)、拉溝面(mian)等(deng)等(deng)。鑿切(qie)(qie)加(jia)(jia)(jia)(jia)(jia)主要(yao)是(shi)(shi)使用(yong)手工(gong)(gong)(gong)(gong)加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong),像是(shi)(shi)錘(chui)、剁斧、鏨子(zi)、鑿子(zi)等(deng),不過有些(xie)加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)過程可以(yi)使用(yong)機(ji)(ji)(ji)(ji)(ji)器加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)完成,重慶石(shi)(shi)(shi)材加(jia)(jia)(jia)(jia)(jia)工(gong)(gong)(gong)(gong)主要(yao)設備(bei)是(shi)(shi)劈(pi)石(shi)(shi)(shi)機(ji)(ji)(ji)(ji)(ji)、刨石(shi)(shi)(shi)機(ji)(ji)(ji)(ji)(ji)、自動(dong)錘(chui)鑿機(ji)(ji)(ji)(ji)(ji)、自動(dong)噴砂機(ji)(ji)(ji)(ji)(ji)等(deng)。

清洗(xi)、檢驗(yan)及包裝(zhuang)加(jia)(jia)工(gong)好(hao)的(de)(de)(de)(de)圓(yuan)(yuan)柱(zhu)(zhu),經(jing)過清洗(xi)、檢驗(yan)、干燥后,重(zhong)慶石(shi)(shi)(shi)(shi)材加(jia)(jia)工(gong)可(ke)以(yi)包裝(zhuang)。圓(yuan)(yuan)柱(zhu)(zhu)的(de)(de)(de)(de)包裝(zhuang)分成兩(liang)個步驟(zou),首先(xian)(xian)用厚度(du)0.5mm的(de)(de)(de)(de)塑(su)料薄膜(mo)將(jiang)圓(yuan)(yuan)柱(zhu)(zhu)包封,然后放入木欄(lan)固(gu)定。包裝(zhuang)、運輸(shu)時(shi)(shi)一定要(yao)注意防止(zhi)磕碰圓(yuan)(yuan)柱(zhu)(zhu)。重(zhong)慶青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)材具(ju)有一定的(de)(de)(de)(de)特性,耐凍,易加(jia)(jia)工(gong),那么隨著它在(zai)建筑行業(ye)的(de)(de)(de)(de)廣泛應(ying)用,如今已經(jing)成為大(da)眾關注的(de)(de)(de)(de)焦(jiao)點,今天重(zhong)慶青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)材帶您來(lai)看一下:關于青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)材安裝(zhuang)的(de)(de)(de)(de)有關介紹,希望以(yi)下的(de)(de)(de)(de)介紹對石(shi)(shi)(shi)(shi)材加(jia)(jia)工(gong)的(de)(de)(de)(de)朋友能有所幫助。1、在(zai)安裝(zhuang)青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)之前(qian),先(xian)(xian)要(yao)做(zuo)好(hao)準備工(gong)作。要(yao)根(gen)據(ju)施工(gong)大(da)樣圖和(he)加(jia)(jia)工(gong)單為依據(ju),同時(shi)(shi)還要(yao)了解(jie)各(ge)部位(wei)(wei)尺寸的(de)(de)(de)(de)大(da)小和(he)做(zuo)法,了解(jie)清楚邊角(jiao)、弧(hu)位(wei)(wei)等部位(wei)(wei)之間(jian)的(de)(de)(de)(de)關系。2、在(zai)正式(shi)鋪沒(mei)之前(qian),要(yao)把青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)按圖案、紋(wen)理、顏色鮮使拼(pin)好(hao),重(zhong)慶青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)材然后再講非整(zheng)(zheng)塊的(de)(de)(de)(de)青(qing)(qing)石(shi)(shi)(shi)(shi)板(ban)(ban)對稱(cheng)的(de)(de)(de)(de)放在(zai)邊沿的(de)(de)(de)(de)部位(wei)(wei),之后在(zai)按兩(liang)個方(fang)向(xiang)編號的(de)(de)(de)(de)排列和(he)放整(zheng)(zheng)齊。

由于磨(mo)(mo)(mo)(mo)拋時(shi)的(de)(de)磨(mo)(mo)(mo)(mo)削力(li)遠小于成型切(qie)(qie)割(ge)時(shi)的(de)(de)切(qie)(qie)削阻力(li),所(suo)以(yi)(yi)裝夾磨(mo)(mo)(mo)(mo)拋圓(yuan)柱(zhu)時(shi),在床頭箱(xiang)一端,只使(shi)用中(zhong)心孔支承即可(ke)(ke)(ke)。視被磨(mo)(mo)(mo)(mo)拋石(shi)材材質不同,磨(mo)(mo)(mo)(mo)拋磨(mo)(mo)(mo)(mo)料(liao)的(de)(de)級配也(ye)有所(suo)區別。如加(jia)(jia)(jia)(jia)工(gong)花崗石(shi)時(shi),可(ke)(ke)(ke)以(yi)(yi)使(shi)用5種粗細(xi)不同的(de)(de)磨(mo)(mo)(mo)(mo)料(liao),加(jia)(jia)(jia)(jia)工(gong)大理(li)石(shi)可(ke)(ke)(ke)以(yi)(yi)使(shi)用“種磨(mo)(mo)(mo)(mo)料(liao)。由于欄桿(gan)柱(zhu)、花瓶等制(zhi)品(pin)的(de)(de)輪廓線(xian)凹凸變化起(qi)伏大,重(zhong)慶(qing)(qing)石(shi)材加(jia)(jia)(jia)(jia)工(gong)使(shi)用上述圓(yuan)環型磨(mo)(mo)(mo)(mo)料(liao){艮難(nan)磨(mo)(mo)(mo)(mo)拋加(jia)(jia)(jia)(jia)工(gong),所(suo)以(yi)(yi)目前仍使(shi)用手(shou)動研(yan)磨(mo)(mo)(mo)(mo)異形回轉體(ti)的(de)(de)簡(jian)易磨(mo)(mo)(mo)(mo)拋設備,完成欄奸(jian)柱(zhu)等制(zhi)品(pin)的(de)(de)拋光加(jia)(jia)(jia)(jia)工(gong)。(二)端面切(qie)(qie)邊加(jia)(jia)(jia)(jia)工(gong)圓(yuan)柱(zhu)的(de)(de)拋光加(jia)(jia)(jia)(jia)工(gong)結束后,可(ke)(ke)(ke)以(yi)(yi)使(shi)用金剛石(shi)鋸(ju)片切(qie)(qie)割(ge)圓(yuan)柱(zhu)的(de)(de)兩(liang)個端面,使(shi)其長度尺(chi)寸(cun)達到成品(pin)尺(chi)寸(cun)要求。必須注意,切(qie)(qie)割(ge)后的(de)(de)端面與(yu)其軸線(xian)的(de)(de)夾角應該略小于90度,重(zhong)慶(qing)(qing)石(shi)材加(jia)(jia)(jia)(jia)工(gong)這樣(yang)在安裝時(shi),接縫才(cai)能小而美觀。

顏色與(yu)質材相得益彰,設計的空(kong)間(jian)會因(yin)此(ci)(ci)(ci)更(geng)加廣(guang)闊(kuo),人(ren)(ren)(ren)的激情(qing)也會因(yin)此(ci)(ci)(ci)而常有(you)常新!人(ren)(ren)(ren)造(zao)(zao)石(shi)(shi)材種(zhong)(zhong)類(lei)與(yu)特點及其石(shi)(shi)材用(yong)途一(yi)、人(ren)(ren)(ren)造(zao)(zao)石(shi)(shi)材的種(zhong)(zhong)類(lei)(1)按出產所用(yong)的材料人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)重(zhong)(zhong)要分為:水(shui)(shui)泥(ni)(ni)型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)、樹脂型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)、復合型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)、燒結(jie)型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)。這四種(zhong)(zhong)制作(zuo)(zuo)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)的方法中(zhong),常用(yong)的是聚(ju)酯型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi),其物(wu)理(li)和(he)化(hua)學(xue)機能好,花紋輕易(yi)設計,有(you)重(zhong)(zhong)現性,適于(yu)多(duo)種(zhong)(zhong)用(yong)處,但(dan)價格(ge)絕對較高(gao);水(shui)(shui)泥(ni)(ni)型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)價錢低廉,但(dan)耐腐(fu)化(hua)性能較差(cha),容易(yi)呈現微龜裂(lie),適于(yu)作(zuo)(zuo)板材而不適于(yu)作(zuo)(zuo)衛生潔(jie)具(ju);復合型(xing)(xing)(xing)(xing)則綜合了前兩者的長(chang)處,既有(you)良好的物(wu)化(hua)性能,本錢也較低;燒結(jie)型(xing)(xing)(xing)(xing)人(ren)(ren)(ren)造(zao)(zao)大(da)(da)理(li)石(shi)(shi)固然只用(yong)粘土作(zuo)(zuo)膠粘劑,但(dan)需經高(gao)溫(wen)焙燒,因(yin)此(ci)(ci)(ci)能耗大(da)(da),造(zao)(zao)價高(gao),而且產品(pin)破(po)損率高(gao)。(2)按使(shi)用(yong)品(pin)名分類(lei)為:1、亞(ya)克力石(shi)(shi):一(yi)種(zhong)(zhong)化(hua)學(xue)樹脂合成材料,清潔(jie),多(duo)用(yong)于(yu)廚房臺面,易(yi)成型(xing)(xing)(xing)(xing),防水(shui)(shui)性好,無色差(cha),但(dan)易(yi)劃傷。

巫山偉奇青石板材公司在(zai)(zai)符(fu)合定(ding)單要求(qiu)的(de)情況(kuang)下,對于一些缺陷不嚴重花(hua)崗(gang)巖制(zhi)(zhi)品(pin)可以進行(xing)(xing)修(xiu)補,即進行(xing)(xing)粘接、修(xiu)補,從而減少廢品(pin)率(lv)。石(shi)(shi)材(cai)鋪(pu)裝(zhuang)前、施(shi)(shi)工中應留神的(de)疑(yi)問1、重慶石(shi)(shi)材(cai)加工前石(shi)(shi)材(cai)鋪(pu)裝(zhuang)之前請詳細閱讀包裝(zhuang)箱上的(de)說明。2、石(shi)(shi)材(cai)為純天(tian)(tian)然產品(pin),紋(wen)路天(tian)(tian)然,有(you)(you)色(se)差,屬(shu)正常表(biao)象。如:洞石(shi)(shi)有(you)(you)洞,砂(sha)巖有(you)(you)砂(sha)眼,片巖表(biao)面多(duo)層次。石(shi)(shi)材(cai)馬賽克選用手工加工技能制(zhi)(zhi)成(cheng),故顆粒之間(jian)存(cun)在(zai)(zai)天(tian)(tian)然差錯,而且顆粒之間(jian)的(de)縫隙也存(cun)在(zai)(zai)天(tian)(tian)然差錯,但不影(ying)響施(shi)(shi)工(施(shi)(shi)工時(shi)可自行(xing)(xing)調整)。3、因石(shi)(shi)材(cai)產品(pin)的(de)質(zhi)地分外性,避免水泥沙漿或有(you)(you)顏色(se)物質(zhi)污染表(biao)面,施(shi)(shi)工場所應堅持清(qing)潔。

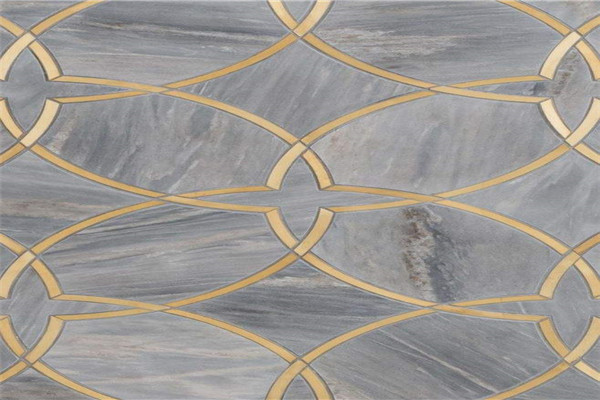

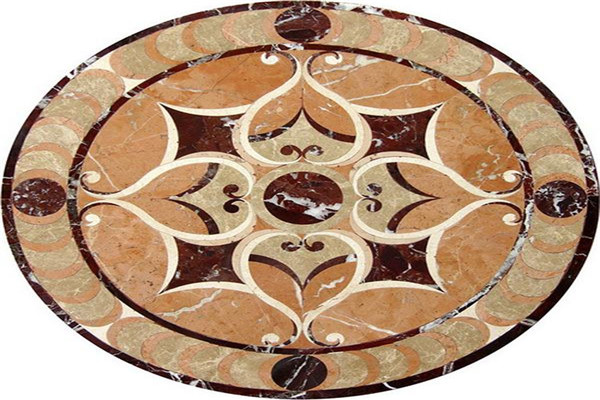

難點縫(feng)隙(xi)小(xiao)現(xian)在的(de)石(shi)材拼花,一(yi)般都(dou)是電(dian)腦(nao)制圖,水刀切割,工(gong)(gong)藝非常(chang)先(xian)進,誤(wu)差(cha)非常(chang)下。往(wang)往(wang)拼裝完成后,縫(feng)隙(xi)只有(you)0.1mm不(bu)到。這么狹小(xiao)的(de)縫(feng)隙(xi),補(bu)(bu)(bu)(bu)膠難度很(hen)高。繁瑣電(dian)腦(nao)制圖,可(ke)設計出極其復雜的(de)拼花。這樣雖然效果很(hen)漂亮(liang),但對補(bu)(bu)(bu)(bu)膠而言,小(xiao)小(xiao)的(de)一(yi)個拼花,都(dou)有(you)可(ke)能是驚人的(de)工(gong)(gong)作量。所(suo)以千萬別把(ba)拼花處理,報(bao)普通工(gong)(gong)程(cheng)(cheng)的(de)價——不(bu)能這么算。補(bu)(bu)(bu)(bu)膠的(de)目的(de)和意(yi)義和普通石(shi)材護理工(gong)(gong)程(cheng)(cheng)不(bu)同,石(shi)材拼花的(de)補(bu)(bu)(bu)(bu)膠處理,還有(you)更重(zhong)要的(de)意(yi)義。實現(xian)真(zhen)正(zheng)的(de)無縫(feng)化拼花雖然可(ke)以做到誤(wu)差(cha)極小(xiao),但必須(xu)通過補(bu)(bu)(bu)(bu)膠,填(tian)補(bu)(bu)(bu)(bu)縫(feng)隙(xi),形成真(zhen)正(zheng)的(de)整體表面(mian)。